CARTON FLOW:

Carton Flow Systems are dynamic shelving units designed to improve efficiency in high-item picking environments. Utilizing a gravity-fed roller or wheel track, products are loaded from the back and automatically move forward for easy access. This system ensures first-in, first-out (FIFO) inventory management, reduces pick times, and maximizes storage density.

Industries Utilizing Carton Flow:

Carton flow is widely used in industries like retail, e-commerce, food distribution, and manufacturing, where quick access to a large variety of products is crucial.

Benefits for High-Item Picking Warehouses:

For warehouses with a high volume of items, carton flow systems streamline the picking process, reduce labor costs, and optimize space utilization, making them an invaluable asset for efficient order fulfillment.

Custom Design & Installation:

Our System Integration team leverages their expertise and your specific needs to design and estimate a tailored solution for your warehouse. We'll assess your space, carton flow requirements, product frequency, load size and weight, and available space to create an efficient plan considering your installation timeline.

Skate Wheel vs. Metal Roller: Which is Right for You?

Straight:

Space Efficiency: Straight systems can maximize vertical space usage, allowing for more levels and storage capacity within a given height.

Simpler Installation and Maintenance: The straightforward design of straight systems can be easier to install and maintain, with fewer parts and potential points of wear and tear.

Product Handling: For products that don't require a gentle transition or are not prone to tipping over, straight flow systems can provide a faster and more direct path, which may be preferable for high-speed operations.

Cost Considerations: Straight systems might be more cost-effective due to their simpler design and fewer components, making them a practical choice for budget-conscious operations.

Knuckled:

Gentle Handling: Knuckled systems are designed to slow down the flow of items as they approach the picking face, reducing the risk of damage to delicate or fragile items.

Improved Product Access: The knuckled design can make it easier for pickers to access products at a more comfortable angle, which is especially useful for smaller or hard-to-reach items.

Reduced Product Movement: By minimizing the speed and impact of products reaching the end of the lane, knuckled systems can help prevent items from spilling or getting disorganized, maintaining a tidy and efficient picking area.

Versatility: Knuckled systems can accommodate a wider variety of product shapes and sizes, making them suitable for operations with diverse inventory that may not flow well in a straight system.

Enhanced Safety: The controlled movement of products in knuckled systems can reduce the risk of accidents or injuries from items falling or moving too quickly.

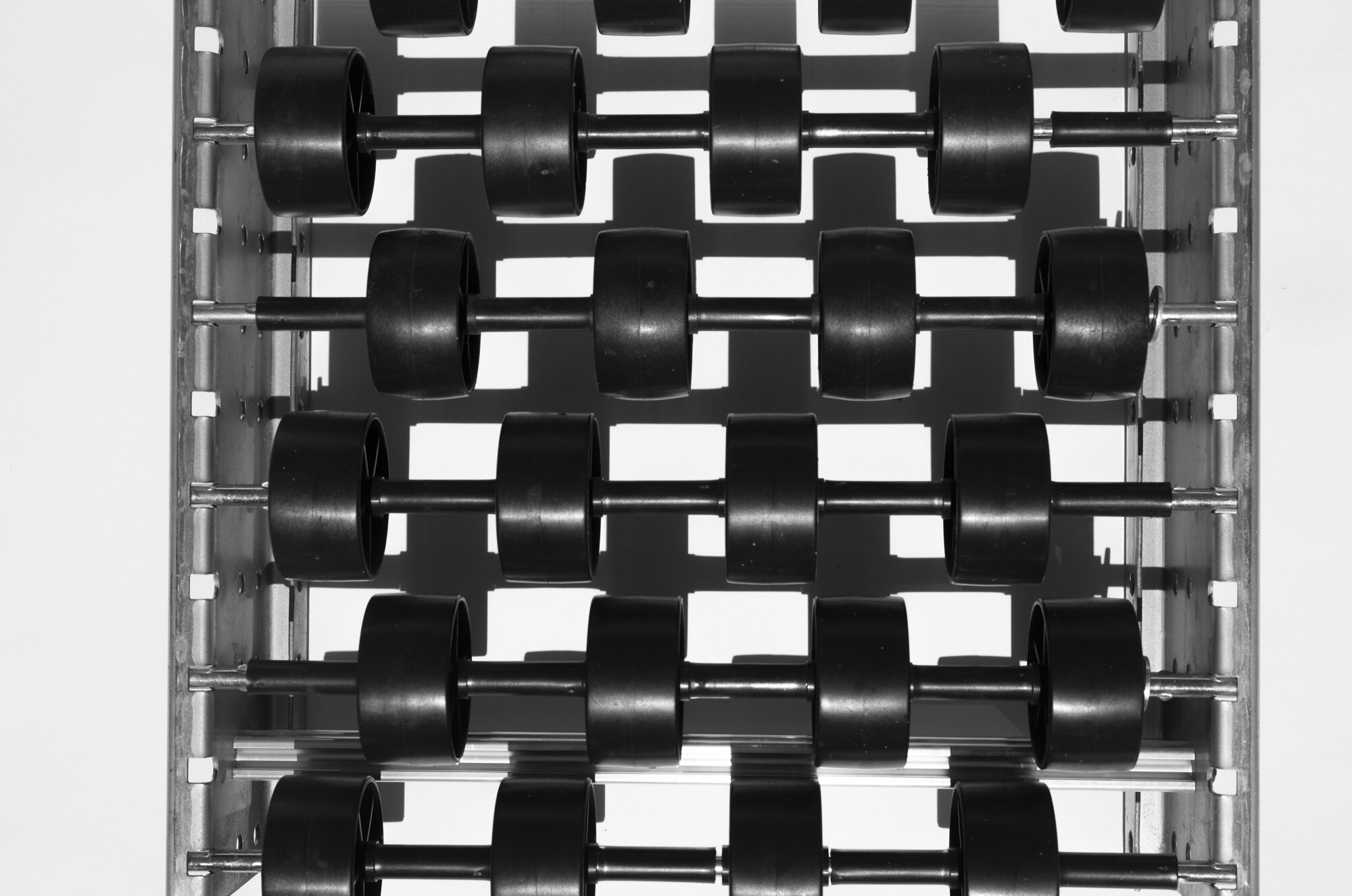

Skate Wheel vs. Metal Roller: Which is Right for You?

Skate Wheel Rollers:

Skate Wheel: Ideal for lightweight and varied packaging, skate wheel systems offer flexibility and smooth movement, perfect for lighter loads and irregularly shaped items.

Metal Rollers:

Metal Roller: Built for durability and heavy-duty use, metal roller systems are great for heavier products and provide consistent, stable support, ensuring efficient handling of robust materials.